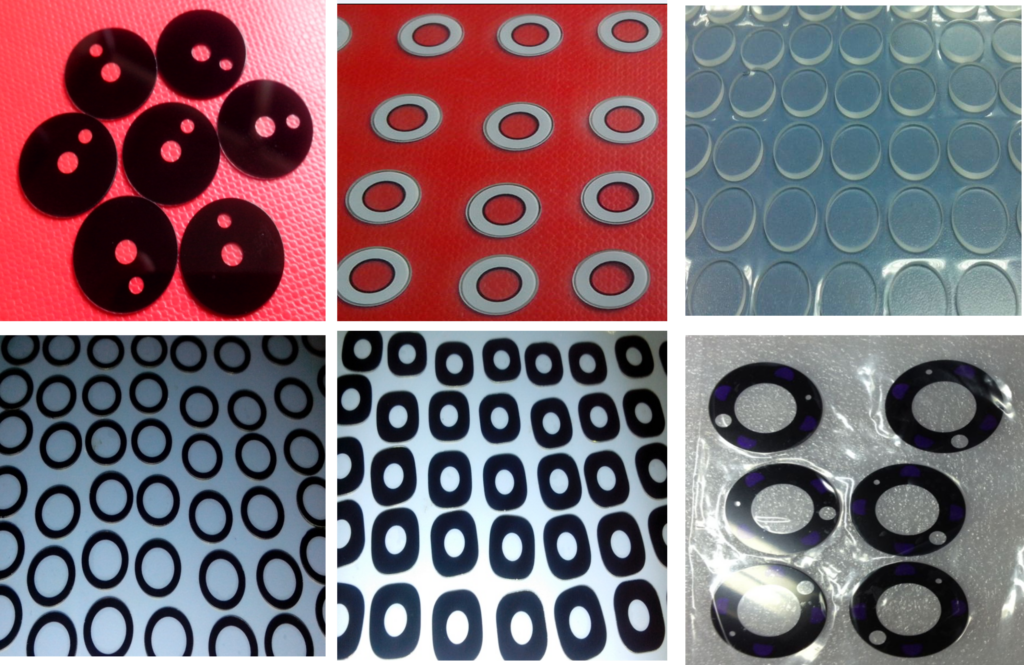

OLPF for SLR and Security Cameras

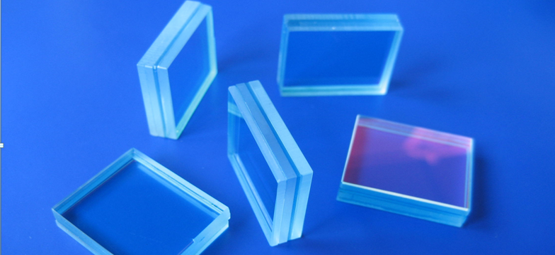

When using CCD or CMOS light sensors such as digital cameras, digital video cameras, CCTV cameras, etc. to capture images, because they use a discontinuous imaging method, when shooting images:

- Unnecessary optical noise will be generated, resulting in stripes in the image, which is inconsistent with the visual perception of the human eye. O.L.P.F is a function that provides the function of eliminating this noise;

- Because CCD or CMOS light sensors can detect infrared parts that the human eye cannot detect when shooting color scenes, resulting in image color distortion, the infrared parts that the human eye cannot detect must be removed. Therefore, it is necessary to coat the surface of O.L.P.F with IR CUT Filter, usually called “reflection type”; or match it with a piece of phosphoric acid glass (commonly known as blue glass), usually called “absorption type”, and adjust the color response within the visible light range (400nm~700nm) at the same time, so that the color presented in the image can meet the perception of the human eye, and give you a real color!

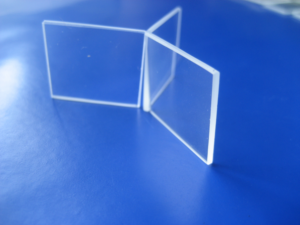

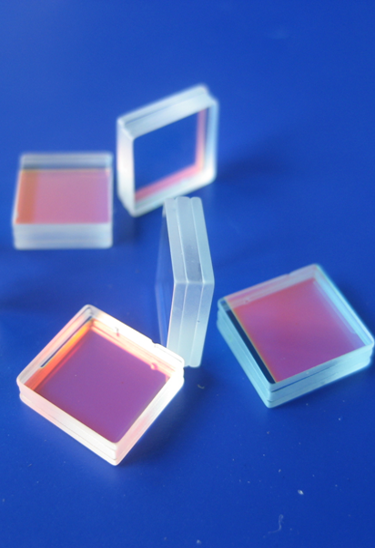

IR-CUT Filter

It is a key component of digital camera phones, PC cameras, video phones, CCTV photoresistors and other products. It mainly coats the surface of optical glass with an infrared cut-off film (IR-CUT coating), which only allows low-frequency light waves within a certain range to pass through, suppresses the passage of light waves higher than the spatial frequency of CCD or CMOS image sensors to cause ripple disturbances, and effectively suppresses infrared light, restores image color, and makes the image clear and stable and in line with human eye perception.

Material: Made of B270, D263T, BK7 and other optical glass surfaces coated with infrared cut-off film; its appearance can be made according to the special requirements of customers

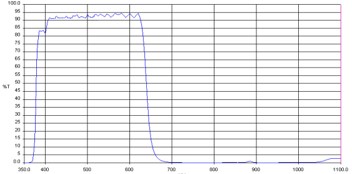

Typical spectral characteristics (can be customized according to customer requirements):

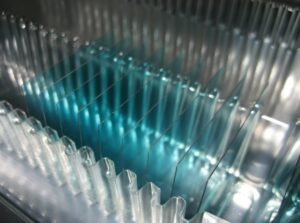

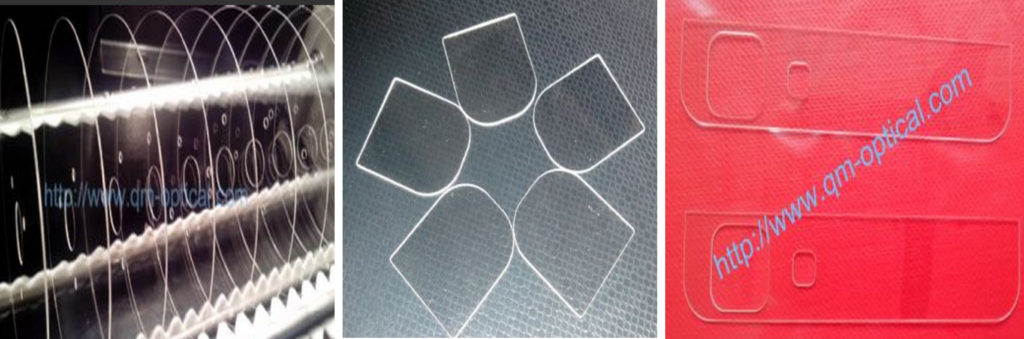

Ultra-thin blue glass for smartphones

Blue glass infrared cut-off filters have a better wide-angle effect than ordinary infrared cut-off filters, high precision, and can remove ghosting produced during photography (videography). They are mainly used in high-definition camera products represented by smartphones with more than 8 million pixels.

Typical spectral characteristics (can be customized according to customer requirements):

| Serial | Thickness | Spec. |

| 1 | 0.30 | 630-650 T=50% Lifespan >1000hr |

| 2 | 0.21 | 630-650 T=50% Lifespan >1000hr |

| 3 | 0.56 | 630-650 T=50% Lifespan >1000hr |

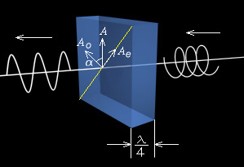

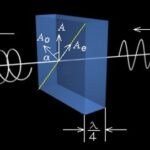

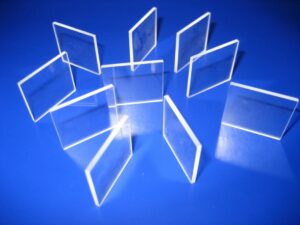

Wave Plate

Wave plate is also called wave delay plate. It is an optical element with two main optical axes, a fast optical axis and a slow optical axis. Through these two optical axes, the incident polarized light will be converted into two mutually perpendicular polarized light rays, which are recombined into a special single polarized light ray. Wave delay plate can achieve full wave delay, half wave delay, quarter wave delay and eighth wave delay.

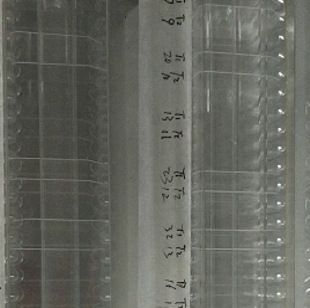

1/2 & 1/4 Wave Plate

An optical element that can be used to convert plane polarized light into circular polarized light or circular polarized light into plane polarized light (as shown in Figures 1 and 2). In order to achieve this change, the direction of the wave plate must be determined first, so that the fast axis or slow axis light wave of the response quantity can be generated. The direction of the incident polarized light can be determined first, so that the incident light and the fast (or slow) optical axis are at a 45-degree angle. When the light passes through the λ/4 wave plate, the light wave changes like when it passes through the λ/2 wave plate, and the polarization plane is rotated at a certain angle. This combination of optical elements is widely used in isolators, Q-switches and other devices.

We can produce products with higher precision up to 5 decimal places, namely 1/2 or 1/4 wave plates. We have already produced several such products of different specifications and thicknesses for customers in Japan and Germany. The thickness of the two-piece glued product is about 0.4mm.

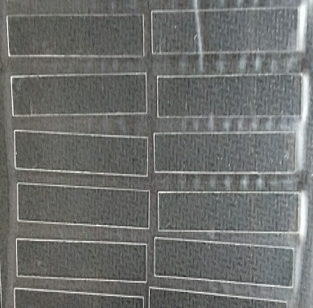

Glued OLPF

Sapphire Windows

Taking advantage of the high hardness, high temperature resistance and wear resistance of sapphire raw materials, we developed a planetary, high-speed rotating, high-capacity sapphire R-edge machine specifically for smartphone window chips, making the tolerance of each side more in line with quality requirements.

Other Sapphire Product

Pure sapphire single crystal has excellent thermal conductivity, electrical insulation, good light transmittance, chemical stability, as well as high temperature resistance, high strength, high hardness and other characteristics. Therefore, it is a window material for infrared devices, missiles, submarines, satellite space technology, detection, high-power lasers, etc., as well as a high-quality optical material, wear-resistant bearings and substrate materials.

Crystal heat sink for projector

Mainly used in projector products, it uses high-quality, light-transmitting, and impurity-free optical-grade quartz crystal (crystal) as raw material. It has birefringence, stability, high temperature resistance, and good thermal conductivity. It can be made into heat sinks of various thicknesses and cutting angles with high phase accuracy.

Sapphire (Sapphire Al2O3) can also be used instead, and sapphire has higher hardness, better dielectric properties, good thermal conductivity, good electrical insulation, high temperature resistance, chemical corrosion resistance, and wear resistance. Its disadvantage is that it is more difficult to process and its price is higher than crystal.

| Serial | Dim. | Angle |

| 1 | 23.5*20*0.50 | 0°/90° |

| 2 | 23.5*20*0.50 | 0°/0° |

| 3 | 23.5*17.5*0.50 | 0°/0° |

| 4 | 20*18*0.50 | 0°/90° |

| 5 | 23.5*16*1.40 | 0°/90° |

| 6 | 21.5*19.5*1.40 | 0°/0° |

| 7 | 27.6*24.5*0.70 | 0°/90° |

| 8 | 30.1*31.8*0.70 | 0°/90° |

| 9 | 36*30*0.70 | 0°/90° |

| 10 | 26*21*0.50 | 0°/90° |

| 11 | 37*31*0.70 | 0°/90° |

| 12 | 28*22*0.70 | 0°/90° |

| 13 | 30*23.5*0.50 | 0°/90° |

Cover glass for mobile phones

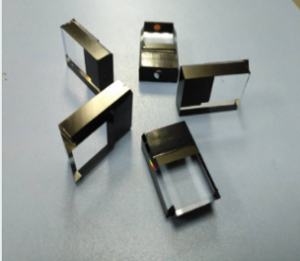

Complex Polyhedron Flat Prism

The prism is mainly used in the collection system and input system of the fingerprint recognition device. The prism can be used to bend light at a specific angle. The prism can not only deflect the light, but also adjust the image direction. The design of the prism will be used to determine how it interacts with the light. When light is incident on the prism, the light will be reflected on a single or multiple surfaces before it is emitted, or the light will be refracted when it passes through the substrate. It plays a vital role in the optical fingerprint collection head. The prism is the most widely used prism in fingerprint recognition devices and has been used for civilian and police purposes.

Prism parameters:

1 Name Complex polyhedron fingerprint prism

2 Material Optical glass N-BK7, K9

3 Size 1-200mm

4 Size tolerance +0/-0.05mm

5 Angle tolerance ±6’

6 Surface finish 60/40, 40/20, 20/10

7 Flatness λ/2 per @633nm

8 Chamfer 0.1-0.5mm

9 Surface accuracy λ/2 @ 633nm

10 Clear aperture >90%

11 Paint Black spray paint or customized

12 Coating Can be coated with AR anti-reflection coating, magnesium fluoride (mgf2), aluminum film, gold plating, silver plating

Other special-shaped products